The success of infrastructure projects requires temporary works to be considered front and centre of the design process. These engineering structures – essential during construction but absent from the final structure – ensure permanent works can be built safely, efficiently, and on schedule.

When temporary works are overlooked during early design stages, projects risk avoidable delays, increased costs, or complicated redesigns.

WCS’s Technical Director, Jeremy Barnes, is an experienced authority in temporary works. He has contributed to Network Rail’s Safety by Design Working Group, helping update guidance on the “Early focus on constructability and temporary works”. In this article, he shares two recent project case studies that illustrate how WCS approaches temporary works in practice, highlighting practical constructability and effective problem-solving.

Case study: Strengthening Morris Street rail underbridge

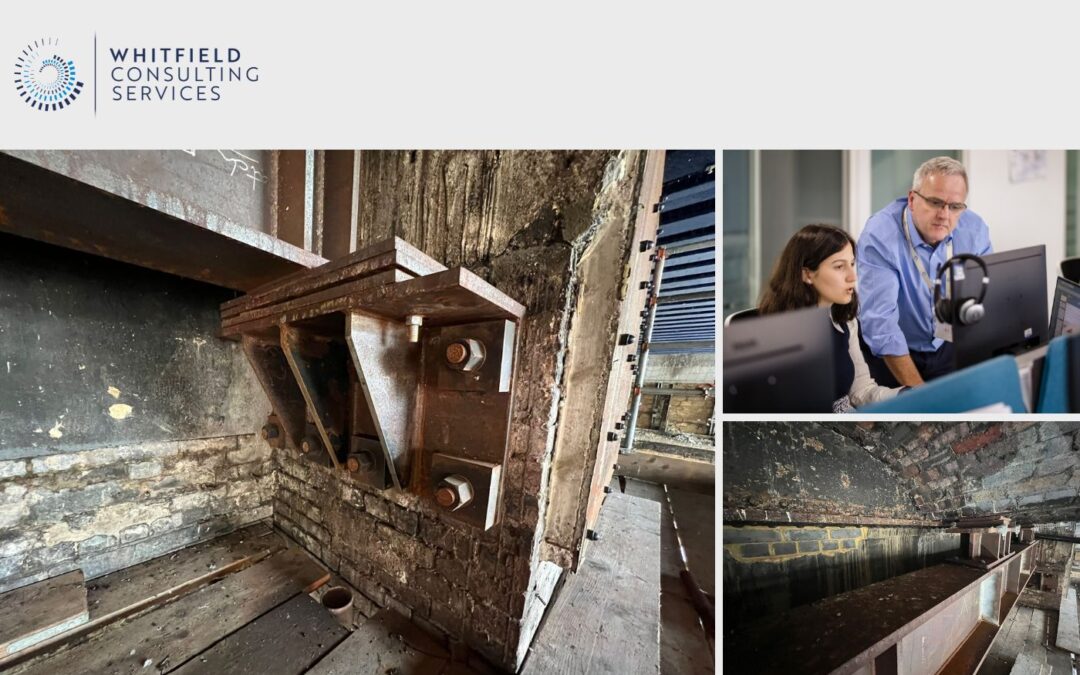

At a rail underbridge in Shadwell, East London, WCS faced a particular challenge: the bridge had to remain fully operational while permanent repairs were carried out on the corroded wrought iron longitudinal girders – all within a severely confined space.

“Access constraints created by an adjacent bridge meant the approach used successfully for the permanent repairs of the other longitudinal girder, was not possible,” says Jeremy. “A temporary support arrangement was therefore required to maintain load capacity until the permanent repairs could be undertaken.”

The bridge’s early-20th-century masonry piers presented another constraint: the load applied to them by any temporary works was limited to avoid cracking. WCS designed a bespoke system of gallows brackets stressed against the piers using Macalloy bars, able to generate sufficient friction, without cracking the historic masonry piers.

To carry the imposed railway load, a stiffened steel plate girder was positioned immediately inside and parallel to the longitudinal plate girder and supported at each end on the existing piers. Steel wedge packs were installed at intermediate jack-arch locations to ensure that the rail-imposed load was fully supported.

“This carefully engineered solution allowed the bridge to remain fully loaded throughout the strengthening works, minimising disruption and risk,” says Jeremy.

WCS delivered design for both the permanent works repairs and the temporary works. Jeremy highlights the advantage of combining permanent and temporary works design within the same team:

“Because we work in both areas, we understand what is required at each stage. We know how our permanent designs will be built, and we know what the site needs to make that build sequence work. It means issues are spotted earlier and resolved before they become problems.”

Case study: Excavation as part of the RIIO ED2 framework

WCS was appointed by UKPNS to design temporary works for a complex excavation project in Hertfordshire, where transformer replacement works were required on a tightly constrained site surrounded by sensitive structures. The team was tasked with designing a soil retaining system to maintain stability of the adjacent structures throughout construction.

“A key consideration was the nearby switching room, where vibration levels had to remain strictly within agreed limits,” says Jeremy. “This requirement influenced both the installation method and the choice of retention system. We developed two options to give the contractor flexibility.”

These were:

- Primary option: a quicker-to-install system without internal props that could be vibrated into place.

- Backup option: a push-and-dig system with internal props, ensuring a viable alternative if vibrations or ground conditions made the primary option unsuitable.

On site, the unpropped vibrated system was adopted, allowing faster installation while keeping vibrations within acceptable limits. The propped scheme remained available as a contingency.

Onsite support during construction

A key part of WCS’s offering isonsite support during construction. For example, on a recent project which involved the design of a 26-metre bridge spanning a river along with 1.2 km of access roads, WCS placed a full-time site representative on location, overseeing both the temporary and permanent works to ensure all works were installed safely and in line with the design.

Senior members of the leadership team also visited site regularly to provide additional oversight and support.

“Being on-site allows us to monitor progress and adjust our design guidance in real time if needed,” says Jeremy. “It ensures temporary works are built as intended and integrate effectively with the permanent structure.”

Temporary Works Coordinator support

Given the nature of construction, with multiple contractors and subcontractors involved in a single project, effective coordination of temporary works is essential. At WCS, we are proud that many of our team members are qualified and experienced to serve as Temporary Works Coordinators (TWC) on projects. As defined in BS5975, the responsibility of a TWC is to ensure all parties communicate effectively, implementing and maintaining the temporary works procedure.

The WCS approach

“When we take on a temporary works design, we start by examining the full construction sequence, temporary conditions and how the permanent structure will be built,” explains Jeremy.

“Understanding constructability is essential. We break the project down stage by stage to see how each element will progress. From that planning, the stage by stage construction sequence and consequent required temporary works – whether supports, scaffolding, or retention systems – naturally emerge.”

“Ensuring temporary and permanent works integrate smoothly is critical,” adds Jeremy. “It helps to ensure that the permanent structure is delivered safely, efficiently, and in line with the design intent.”

Learn more about WCS’s capabilities in temporary works:

- See our infographics detailing our service offering for Rail and Power & Energy projects

- Visit our temporary works design & coordination service page to view some of our recent projects

- Read further insights into temporary works with related articles: The risks of overlooking temporary works design and coordination in infrastructure projects and Full and early collaboration between permanent and temporary works designers is vital to constructability and the control of cost and risk

If you need a temporary works consultant for your next project, please call us on +44 (0)20 8938 375, or email info@wcs-consult.co.uk.