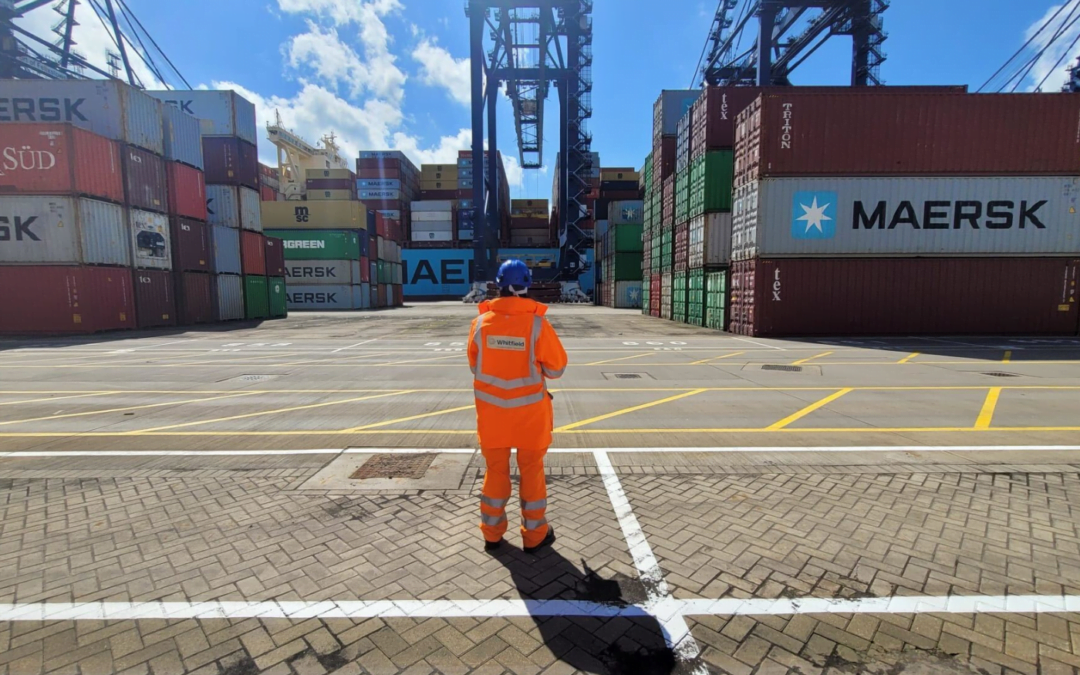

The Port of Felixstowe is Britain’s largest and busiest container port. Even so, the port is committed to a major upgrade of facilities which will involve renewal of much of its infrastructure.

Main contractor UK Power Networks Services (UKPNS) was engaged to complete two critical elements of this work, and turned to Whitfield Consulting Services (WCS) to handle the early stages of the projects – ground survey and engineering design.

Enabling the switch from diesel to electrified tractor-units at Trinity Terminal

When a container needs to be moved from a warehouse to the dockside cranes, for example, it will be pulled by an Internal Movement Vehicle (IMV). An IMV, also known as a tractor unit or tug (and not to be confused with a tugboat), is essentially an HGV cab that can be connected to a trailer upon which a shipping container or other load is placed. These are specialised units that spend their entire working life within the port, and don’t venture onto the general road system.

The current IMV fleet at Trinity Terminal burns diesel fuel. As well as an expansion in capacity, Port of Felixstowe is committed to an ambitious reduction program for its carbon footprint. One important element of this is the switch to a fully electrified IMV fleet at Trinity Terminal. To enable the new IMVs to operate, two new Electric Vehicle Charging Substations need to be built, and power carried from the grid to these two sites.

The first stage of activity for WCS was to oversee a validation of the ground conditions through intrusive investigation – boring deep into the soil across the site to establish the composition and firmness of the ground upon or within which everything else will sit. This was needed for the locations of the two proposed new EV Charging Substations, but also for the whole of the route of the cabling that will be needed to carry power to these charging stations. Full design of the cabling system, with its service pits and ducts was also required. This design required the weaving together of new infrastructure with existing pits and ducts, where available.

A port is an especially challenging environment for such work, with water obviously having the potential to create poor ground conditions. This also means buildings around the port are quite likely to have heavier foundations, such as piling, so many potential ‘blockers’ exist to any underground cabling system.

In addition to designing this complex system, WCS were asked to create designs for the foundations of the new substations, as well as to provide design co-ordination and civil design support to UKPNS throughout the project.

The survey and design for the Trinity Terminal project is now complete, though WCS continues to liaise with UKPNS and various specialist subcontractors who use our engineering designs.

Enabling the switch from diesel to electrified yard cranes at Berths 8&9

The Port of Felixstowe was originally called The Felixstowe Railway and Pier Company. Under that name, it dates back to 1875. But the modern port dates really to 1967, when Landguard Terminal was opened. The original Landguard terminal was redeveloped as Berths 8&9 in 2011.

Once again, main contractor UKPNS turned to WCS for survey and design work, this time for an ambitious project involving units that dwarf the tractor IMVs discussed above.

A forty-foot shipping container, full loaded, might weigh thirty tonnes. Lifting these up into the air and then back and forth along the dockside will be the task of Felixstowe’s electrified Rubber Tyred Gantry cranes. As with the IMVs, these proposed units are replacing a diesel solution as part of the decarbonisation drive.

The undertaking WCS was tasked with again started with intrusive ground investigation, before moving on to engineering design centred on foundations and a high-voltage cabling system, complete with draw pits for maintenance and ducts as needed.

In this case eight charging substations were needed, along with a high-voltage cabling system bringing 11,000 volts more than a kilometre to the substations. As well as all the usual challenges of a port environment, the design had to accomplish a rail crossing and road crossings, including that of the main road into the port. Facilities like Port of Felixstowe need to offer their customers ceaseless efficiency and 24/7 operation, so it was never going to be possible to close the main access road while traditional trenches were dug. Instead, horizontal directional drilling was used to tunnel under the road while it remained in use.

Whitfield Consulting Services’ work at Berths 8&9 is drawing to a close, though we will no doubt remain in consultation with UKPNS and others as they proceed to implement our designs.

To find out more about this project, or to enquire about your next project, please visit our contact page.